Tailored Magnesium Alloys for Improved Lightweighting

Magnesium alloys have tremendous lightweighting potential in the defense, aerospace, and transportation industries due to their high weight-to-strength ratio, amongst other advantageous characteristics. The Daly group investigates interactions between microstructure and mechanical properties, towards the goal of improving component design and predictive capabilities of the material response of Mg and its alloys under a range of thermo-mechanical loading conditions. Recent and on-going work in this area includes the characterization of the effects of grain size strengthening and the influence of alloying on the Hall-Petch relationship, as well as the investigation of microscale deformation processes including twinning and microcracking and their evolution as a function of microstructure and loading conditions.

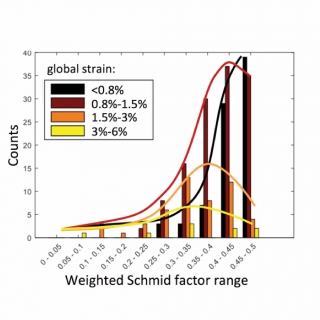

While previous work on microstructural effects in Mg alloys has been largely computational due to the complexities of its experimental characterization, our research group has recently used chemically-assisted nanoparticle deposition, digital image correlation, and distortion-corrected scanning electron microscopy to quantitatively map the full-field microscale distributions of slip systems, twinning, and other deformation mechanisms in magnesium alloys for the first time. This approach is being developed in combination with automated SEM to collect hundreds of millions of data points of nanoscale deformation, and microstructural characterization of the surrounding features of each data point in large-dimensional space, for use with the concurrent development of statistical frameworks to differentiate between stochastic information and deterministic trends in microstructure-deformation relationships.