New Experimental and Analytical Methodologies for Material Characterization

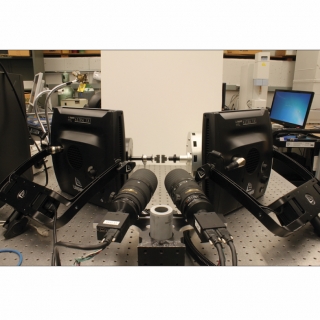

While material characterization has always been of fundamental importance, the need for quality characterization growing as the current demands on the performance-related properties of materials increase. Establishing a relationship between the microscopic behavior of a material and its macroscopic properties is critical for the systematic development of new materials and the prediction of their behavior in practical applications. The need for new methods to facilitate the experimental characterization of materials on the multi-scale, and analytical frameworks to interpret the data resulting from emerging methodologies, have arisen as a natural part of our research. In the course of our work, we have developed methods for microscale deformation tracking, including the development of a number of chemically-assisted nanoparticle formations on metallic alloys, ceramics, and corrosion susceptible alloys; increased the accuracy of macroscale digital image correlation by introducing cross-polarization techniques; created new MEMs devices for in-SEM testing of small-scale specimens; performed research studies using a number of custom-modified macroscopic testing rigs for fracture and deformation in structural modes; utilized a novel in-SEM fatigue testing system to examine environmental effects on titanium alloys in the very high cycle regime (VHCF system designed and built by Mr. Chris Torbet, UCSB); and are in the process of creating a high cycle fatigue system for ex-situ and in-SEM testing, with ex-situ elevated temperature capability. Many of these methodologies result in large data that require the concurrent development of statistical and unsupervised learning frameworks for their interpretation, which is an on-going effort in the group.