Functional Materials

Functional materials are materials in which the mechanical behavior is coupled with outside influences, such as temperature or magnetic fields. These materials are coming into increasing use in a wide variety of applications because of the unique properties that arise from these couplings. Examples include shape memory alloys, piezoelectric materials, and magnetostrictive materials.

One focus of our research group is on providing a quantitative understanding of the heterogeneous nature of deformation and failure mechanisms in shape memory alloys (SMAs). The SMA Nickel-Titanium (Nitinol) is widely used in bio-medical and MEMS applications, and is an important model material when considering interactions between length scales. It is unique in that the deformation is inhomogeneous at several length scales. At the sub-grain level, there is martensitic phase transformation inside the grains; at the scale of the grains, we see inter-granular effects; and at the scale of the specimen, there is martensitic strain localization in the form of Luders-like bands. We seek to connect deformation mechanisms at different length scales – for example, the interactions between heterogeneous transformation at the microstructural length scale and the observed macroscopic behavior – and to understand how we can tailor this material, and others, for optimal use.

On the macroscale, this research includes the experimental investigation and modeling of SMAs under structural modes including bending, tension, and torsion. Recently, we found a remarkable memory in the manner in which clusters of grains undergo phase transformation and accommodate strain during cyclic loading, amongst other findings. Further investigation revealed that microstructure plays a significant role in the amount of strain memory observed, with unfavorable transformation textures (unfavorable being determined by both theoretical and experimental considerations) leading to a greater amount of transformation similarity. Although it is clear that texture plays a large role in the response of these materials in application, there were limited quantitative, spatial measures of transformation at the microstructural length scale due to experimental limitations. We are working on the quantitative mapping of spatial measures of transformation at the microstructural length scale, which has resulted in findings including that similarly oriented grains do not transform similarly, and that sub-grain detwinning happens much earlier in the stress plateau that originally assumed and is locally linked to residual damage.

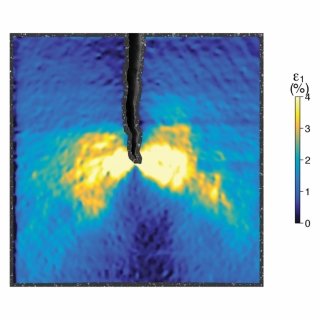

We are currently focusing on the fatigue and fracture mechanics of SMAs, as the phase transformations that provide remarkable properties in SMAs, such as the shape memory effect and superelasticity, also create uncertainty for durability predictions. Recent work has included new measurements of the deformation and phase transformation behind stable growing cracks in superelastic PT NiTi (an important alloy for medical devices such as stents and heart occluders), and the first crack growth measurements of a promising new shape-memory alloy (nanocrystalline NiTi) in collaboration with the Shaw group at the University of Michigan and the Sun group at the Hong Kong University of Science and Technology.