Deformation Mechanisms at Grain Boundaries (MEMs to Macroscale)

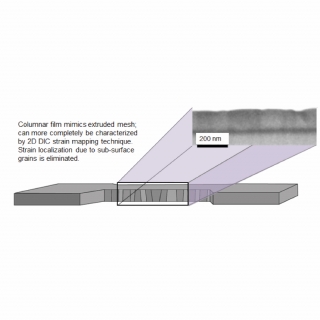

Dislocation slip and grain boundary sliding are centrally important to the behavior of polycrystalline metallic materials, but little is known about the interactions between these mechanisms during plastic deformation. We are working on determining the relationships between microscale deformation mechanisms in polycrystalline columnar FCC specimens, with a current focus on decoupling the slip and grain boundary sliding at grain boundaries in oligocrystalline 99.999% aluminum. It is believed that a synergistic relationship exists between these mechanisms. Due to their nanoscale thickness, large width to thickness ratio, and columnar grain structure, oligocrystalline FCC specimen can be approximated as a two-dimensional material. In this case, a plane stress approximation can be used, and dislocation glide and GBS mechanisms can be characterized without sub-surface ambiguity, unlike the case with bulk material. In-SEM testing of macroscopic and microscopic specimens are combined with techniques including microscale deformation tracking, custom MEMs testing devices for in-SEM characterization, electron backscatter diffraction, transmission Kikuchi diffraction, and scanning transmission electron microscopy to examine the deformation mechanisms active at grain boundaries in a model material of high purity aluminum. Analysis includes the development of frameworks for statistical analysis of spatially distributed deformation mechanisms with respect to the underlying microstructure, and approaches for large-data analysis. Collaboration with the Sangid group at Purdue University is underway to connect experimental results to crystal plasticity modeling in an iterative model-experiment feedback loop.