Constituent Architecture Effects on CMC Response under Elevated Thermo-Mechanical and Environmental Loads

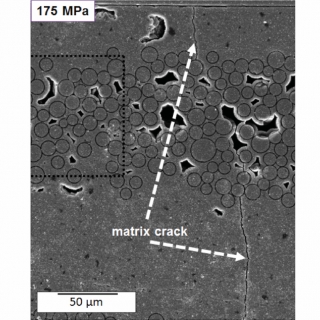

Silicon Carbide/ Silicon Carbide ceramic matrix composites (SiC/SiC CMCs) are candidate materials for extreme environments due to their low weight, advantageous creep behavior, high specific strength, and oxidation resistance at temperatures exceeding 1400°C. CMCs can withstand cycling at exponentially higher loads than metals, and can be laid up into complex shapes, which greatly expands design options. However, long-term exposure to the elevated temperatures, stresses, and environments encountered in-operation causes degradation in these advanced composites, which is one of the primary barriers to their widespread use. In order to predict and improve their durability for space and other extreme environment applications, it is imperative to characterize and analyze their deformation and failure mechanisms under complex thermo-mechanical loading conditions, and to examine how to best mitigate their degradation through the guided layup of their constituent components. Towards this aim, there is on-going research in the Daly group towards the quantitative characterization of the impact of the three- dimensional architecture of composite constituents on the initiation and accumulation of damage (including crack opening displacements and densities), as a result of factors such as applied stress, elevated temperature, and mechanical and chemical environment.